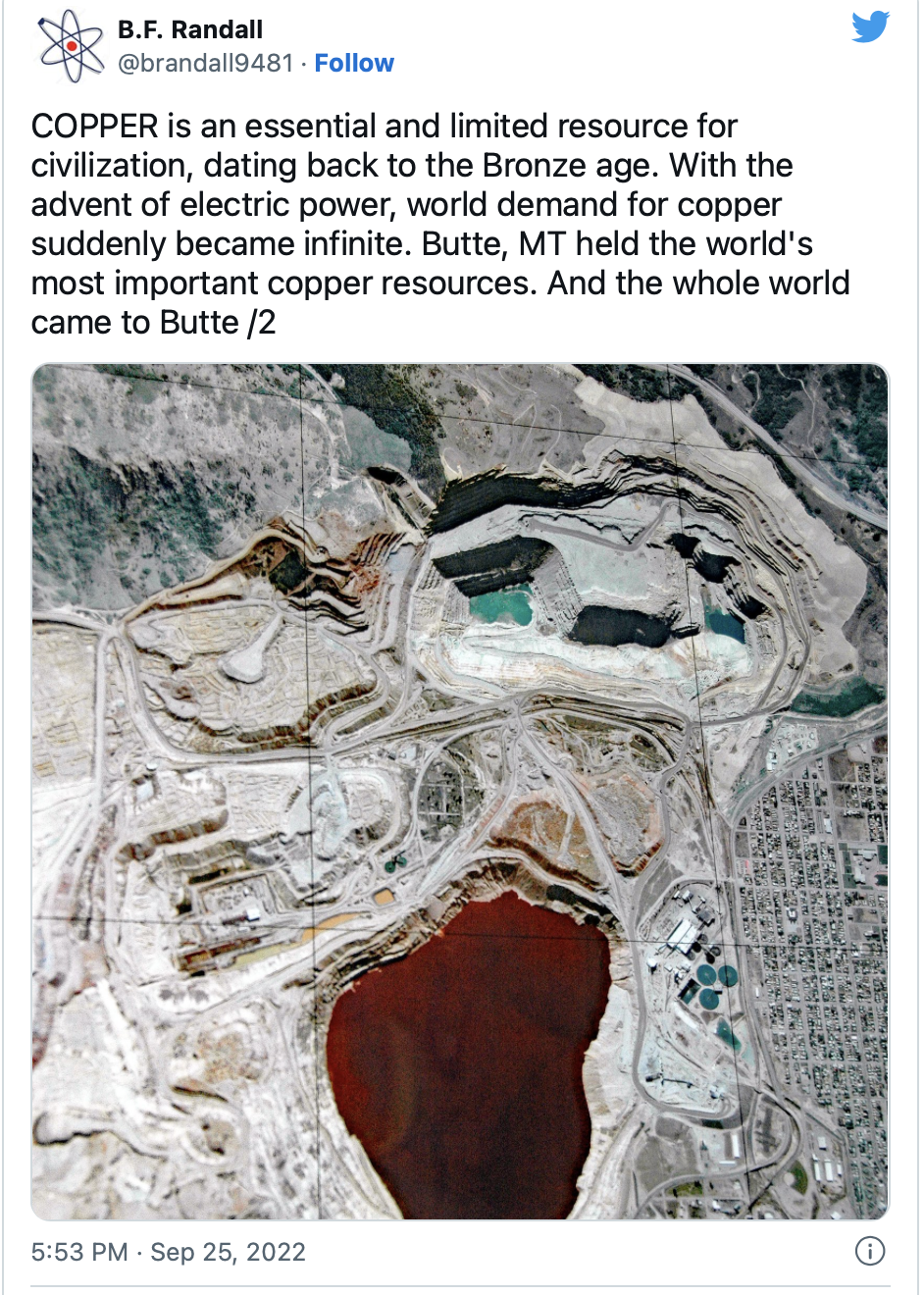

In anticipation of the howls for "green" energy sure to follow in the wake of Himmicane Ian, here's a bit of solid fact, sure to be ignored

/John Hinderaker, Powerline:

REALITY BITES WIND

It is an article of faith among many governments that we are in the midst of a transition from fossil fuel energy to “renewable” wind and solar. (Notably absent from this consensus are China, India and Russia.) In fact, no such transition is underway; wind and solar account for only a derisory portion of the world’s energy consumption, despite countless billions in subsidies. Nor will any such transition happen at any time in the future.

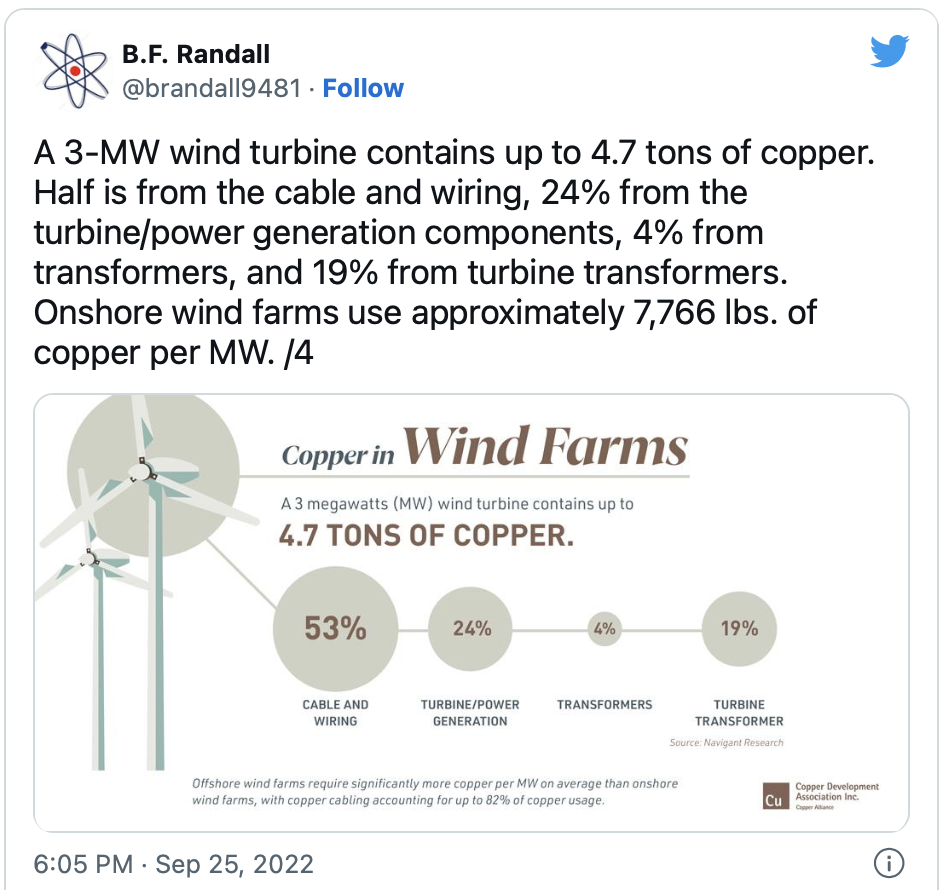

One of the fundamental problems with wind and solar is that they are ridiculously low-intensity. As a result, it requires a vast quantity of raw materials to produce a modest, and unreliable, amount of energy. Did you know that a single wind turbine requires 8,000 pounds or more of copper? Like me, you probably have no concept of what it takes to produce that quantity of copper, or of the vast amounts of fossil fuels that are needed to create just this one component of a wind turbine. Wind and solar installations are parasitic: they cannot be produced without using enormous quantities of fossil fuels.

This thread is one of the best explanations I have seen of the absurdity of wind turbines, as it relates to a single raw material: copper. Please read the whole thing, and bear in mind that copper is just one of a number of minerals that wind turbines and their mythical “batteries” require in enormous quantities. Cobalt and lithium are among the others.

NOTE: Long as this excerpt is, the original is longer: I read it yesterday, but can’t find it today. This excerpt leaves out a crucial fact: the copper wire essential to these turbines must be made from virgin copper; for reasons explained by the author in his original tweet thread, recycled copper can’t be made uniformly fine enough.

For copper processing, size reduction is essential so typical blasting patterns are small. That means lots and lots of holes through hard rock. It can take weeks or months to drill out a single bench. Tungsten carbide drill bits are essential for economical drilling. /6 pic.twitter.com/86AP3JJMqa

Then comes the fun part: BLASTING. Ammonium Nitrate / Fuel Oil -ANFO- is the primary blasting agent. It's 94% ammonium nitrate with diesel fuel oil. AN is manufactured from methane and requires a great deal of fossil-fuel energy and associated emissions. /8 pic.twitter.com/3QeQjXo70x

Steel to manufacture the equipment; tires; lubricating oil; grease; fuel; maintenance; batteries; wear steel; and associated transportation, mobilization, and demobilization – 100% consumptive just to pick up and move rock. /10

Next comes milling & grinding. Copper ore is hard and must be milled down to a fine sand. This step consumes vast amounts of electrical energy, which must be 100% reliable, 24/7, so much so that most copper mines operate their own power plants. Coal/gas. /12 pic.twitter.com/vwc8dDiam4

— B.F. Randall (@brandall9481) September 25, 2022

The KUC tailings pond enormous. Its construction to date has required moving tens of millions of tons of soil, rock, clay, and cover material. It's an engineered system, requiring the use of tens of millions of tons of processed, washed, screened, and imported sand and gravel /13 pic.twitter.com/ARWGUG7qxo

— B.F. Randall (@brandall9481) September 25, 2022

Next, the concentrates (24% Cu) are smelted using coal. No other fuel will do. The KUC ore is high in sulfur. Most is removed and converted to acid, but some is released. My kids and I breathe this daily. The carbon / FF used in this step are astronomical. But we aren't done /15 pic.twitter.com/cZZxbgeent

— B.F. Randall (@brandall9481) September 25, 2022

The end result of the mining process is new cathode copper. I directly challenge analysts calculating lifecycle impacts of VRE to account for the fossil fuel and carbon impacts expended in producing new cathode copper. Every step before cathode is 100% consumptive. /17 pic.twitter.com/EJNDKmOITM

— B.F. Randall (@brandall9481) September 26, 2022

Copper cathode is transported (diesel fuel) to a rod mill, where it is melted in an electric arc furnace and turned into rods and then wire. The EAF requires vast amounts of dispatchable electric energy. Wire is then shipped to the turbine manufacturer. /19 pic.twitter.com/huKee9be5Q

— B.F. Randall (@brandall9481) September 26, 2022

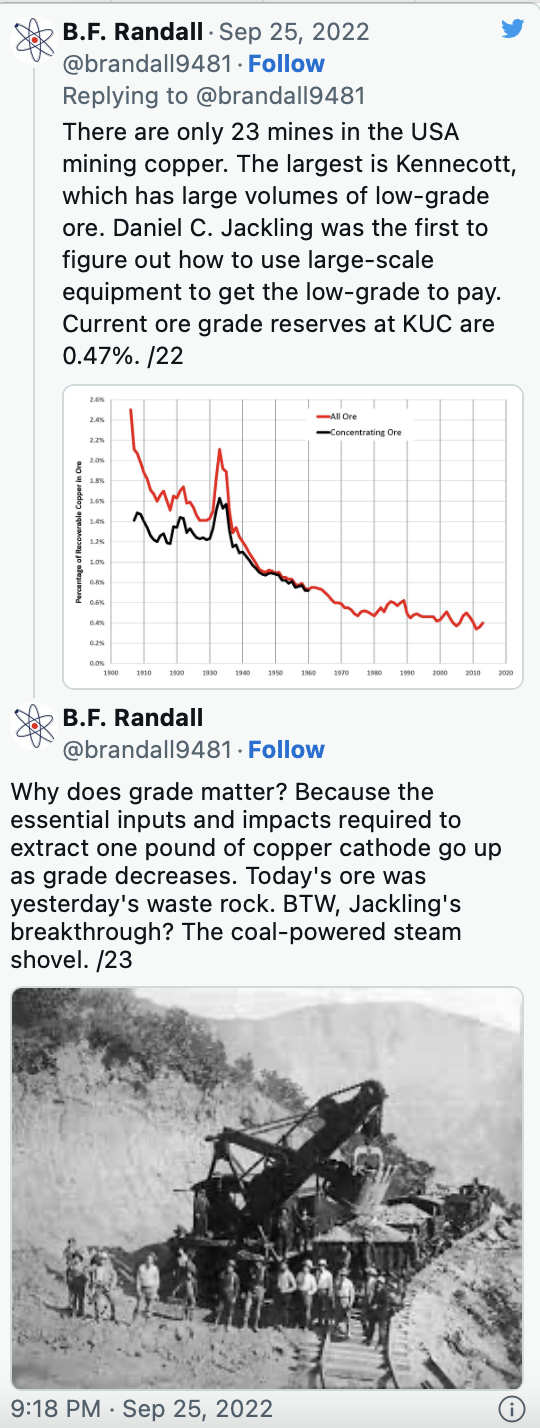

Since Roman times, copper ore grades have been decreasing, astronomically so since Edison's and Tesla's inventions electrified the planet. This is a function of the natural occurrence of copper in earth's crust and the cost of extracting it. Commodity economics. /21 pic.twitter.com/RQb9sPJhlX

— B.F. Randall (@brandall9481) September 26, 2022

t's hard to describe the internal amusement I experience every time a Wind/Solar/Battery advocate lectures me about the imminent depletion of uranium and thorium fuel or the contention that nuclear energy is "not renewable." Windmills Forever! /25

— B.F. Randall (@brandall9481) September 26, 2022

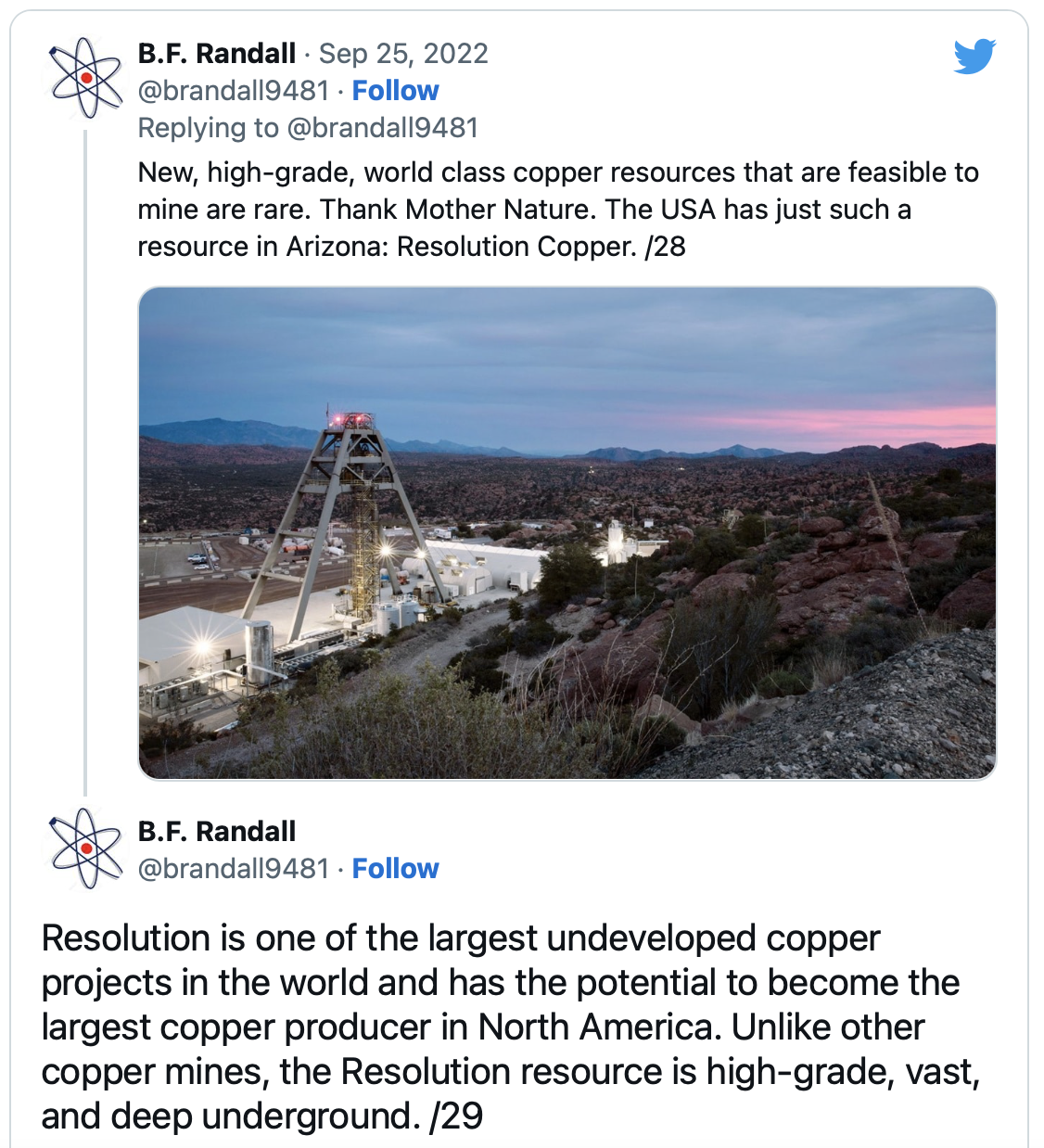

ALL of the copper mined on earth prior to the advent of wind/solar energy was essential to civilization for uses unrelated to wind/solar. Copper requirements will continue and will even expand with technology development. Such is competing with wind/solar. /27